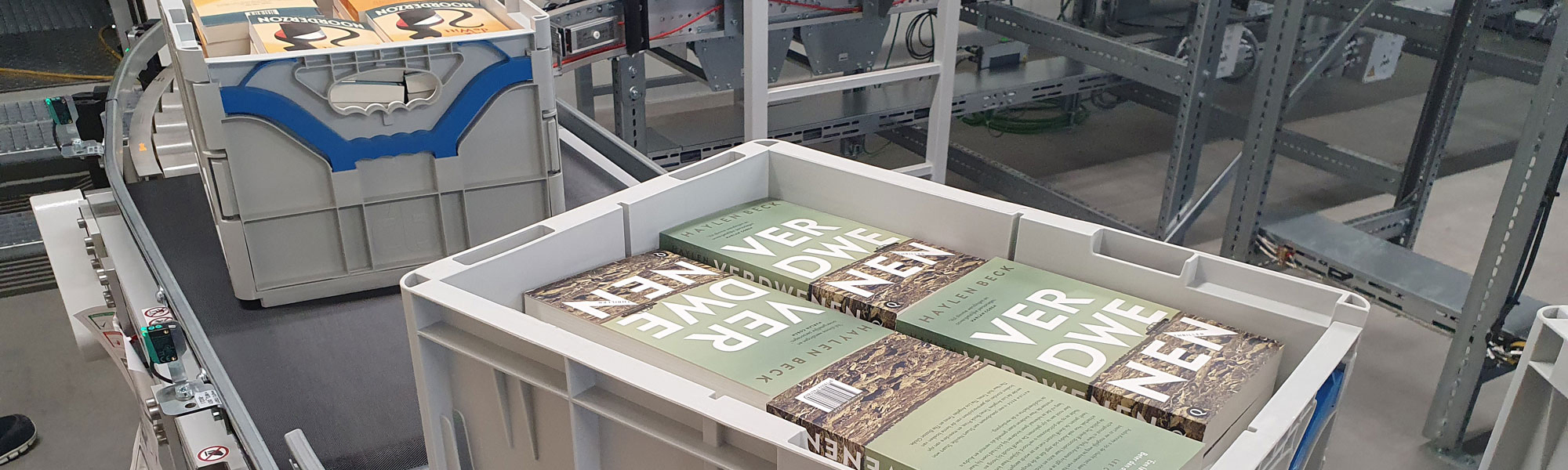

Order picking within 2.5 hours in a DC with 160,000 products. This is now possible thanks to the 200,000 picking bins from Engels!

CB, formerly known as Centraal Boekhuis, distributes physical books and e-books and offers logistics solutions for the Healthcare market. In 150 years, CB has grown into an international logistics expert with several distribution centrres in the Netherlands and Belgium.

In the central bulk warehouse, CB ran into difficulties getting the 160,000 different products to the right stock and pick location in time. The number of orders has been increasing for years, while the size of the orders was getting smaller. The need to store and pick small quantities made the construction of a new warehouse essential for CB. To keep up with the developments, CB build a whole new automated warehouse with a height of 30 metres.

Fast and efficient order picking

Getting the products to the right place internally as quickly as possible, to order pick them. That is one of CB's main goals. With a choice of 160,000 products and orders that have to be picked within 2.5 hours, is easier said than done. A shuttle warehouse with order picking bins turned out to be the best solution.

200,000 picking bins for shuttle warehouse

In order to make use of the expanded capacity, CB initially issued a tender for 200,000 miniload containers, identical to and to expand the approximately 60,000 existing warehouse containers.

However, it soon became clear that the existing warehouse bins, the design of which is already about 40 years old, had to be adapted in order to function optimally in the new shuttle warehouse. The tender was rewritten with the requirements for an alternative and improved design of the existing barge. As a specialist in plastic containers, Engels was happy to take on this challenge.

Some requirements for the new storage and transport bins:

The newly constructed picking bins should have exactly the same internal and external dimensions as the existing order pick bins, because all calculation models for the filling level of the warehouse bins, as well as the existing automated systems, are set up accordingly.

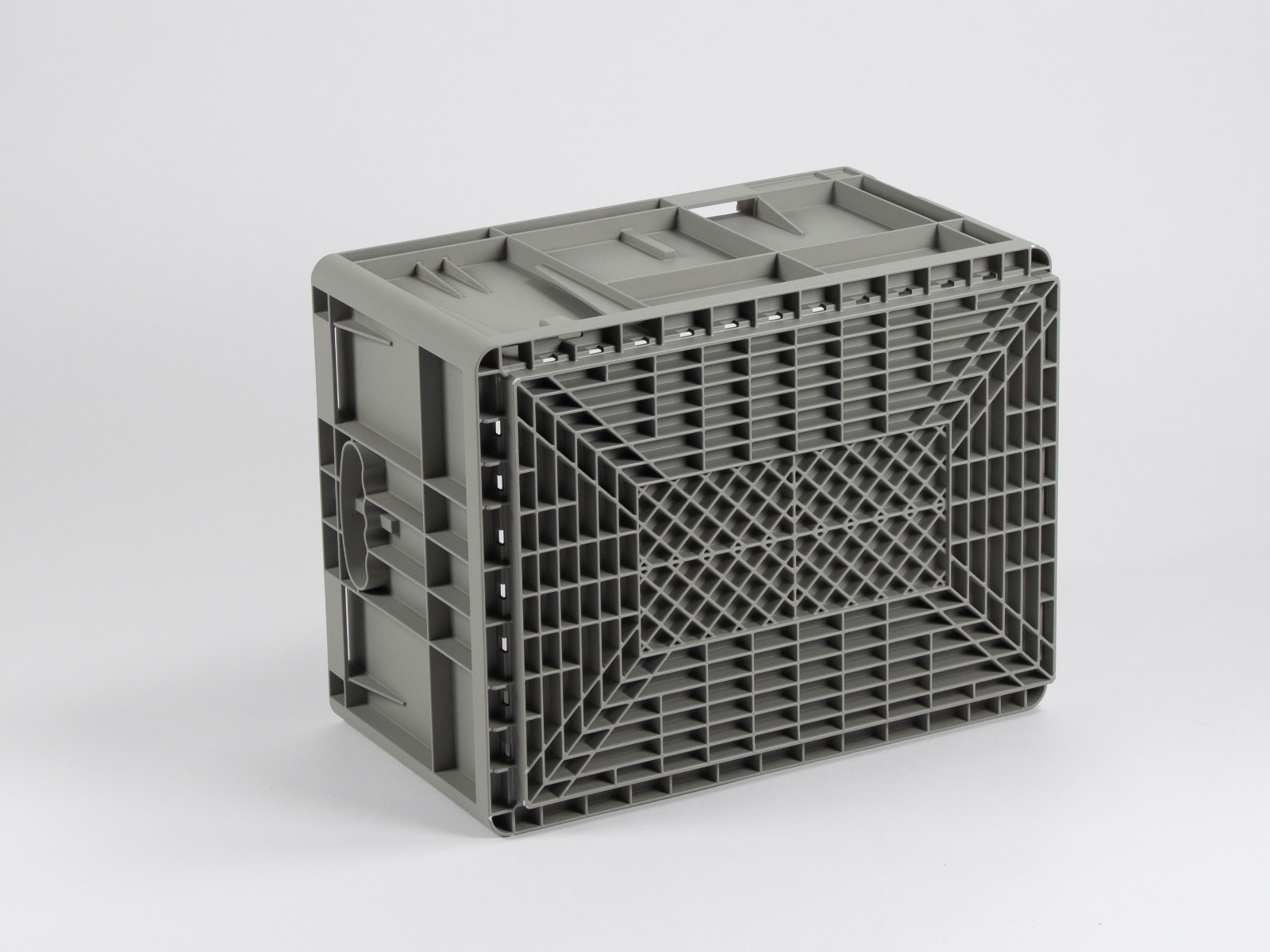

Be able to carry a load of 30 kg of books without deforming the bottoms.

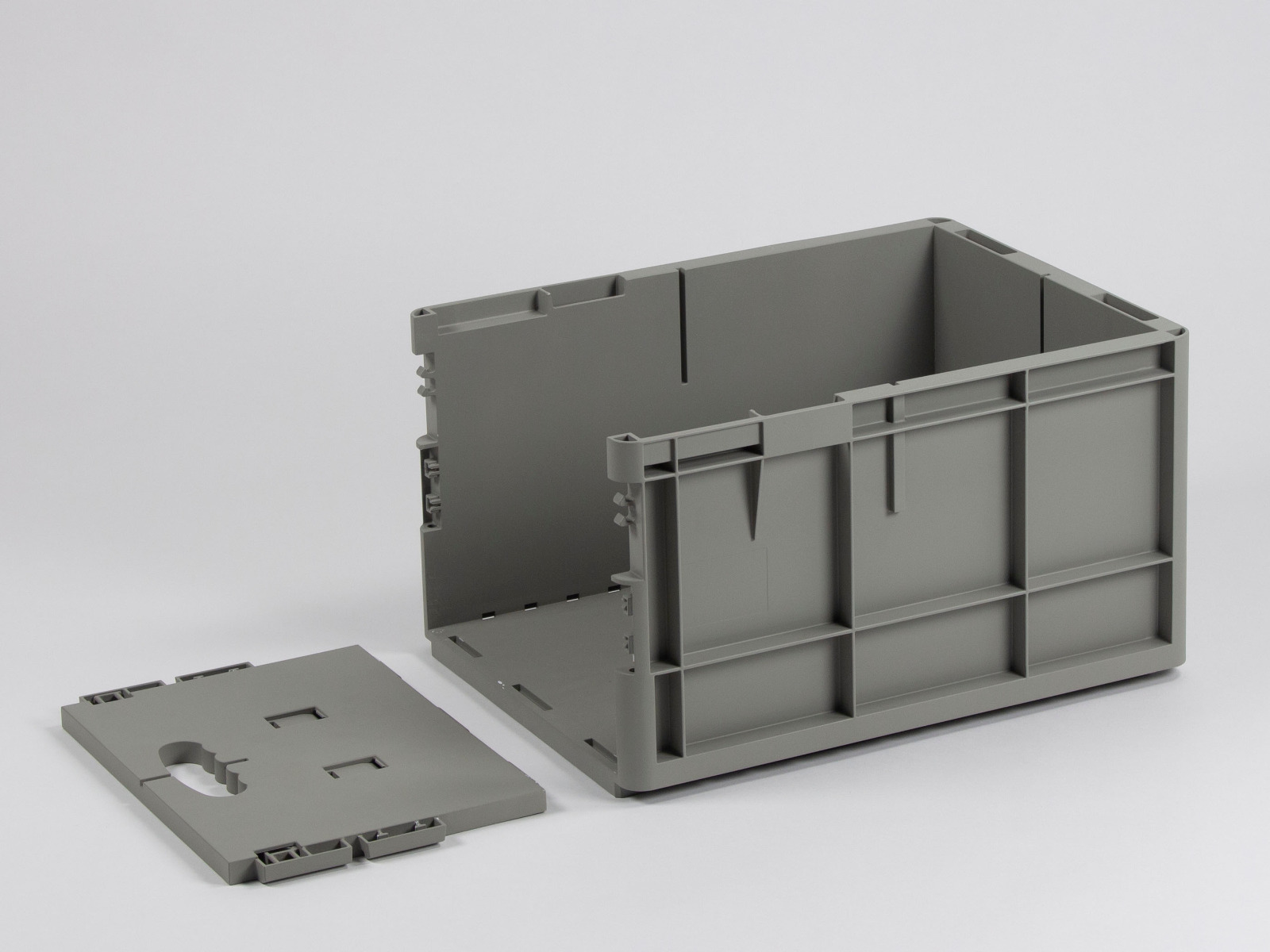

Like the existing plastic bins, a fully removable front, which with a capacity of 30 kg can also be lifted into the removable front by the handle.

Provided with drainage openings by order of the fire brigade and insurance company, so that the storage bins do not fill with water when the sprinkler system is activated.

Finally, CB wanted a provision in the bins for fitting dividers, in order to be able to compartmentalize for the storage of small items and/or slow movers.

The designs of our R&D departments were critically examined during the process and refined according to CB's wishes. The 3D model provided by Engels has been assessed by all stakeholders, from the technical department to the logistics staff and the system integrator. The physical tests on the roller conveyors with transfer units, pushers and re-stacking with the bin robot also proved to be no problem for the Engels design. This has resulted in a practical and flexible plastic container, suitable for both storage and mechanical internal transport.

- 200,000 miniload bins

- Stackable

- The flap at the front is completely removable and can be placed in the top edge of the bin.

- Front with ergonomic handle and robust, spring-loaded multi-point locking.

- Unique fixed barcode per bin, recessed in both long sides.

- Integrated document holder for temporary (internal) accompanying documents.

- Rounded, double-walled corners on the outside for better conductivity and absorbing shocks and impacts.

- Strong running gear bottom; ensures stability of the container, offers good grip on conveyors and makes little noise on roller conveyors.

- Slots for optional dividers; flexible use, multiple types of products in 1 container.

- Smooth inner walls prevent damage to products and are easy to clean.

- Drainage openings, so that water does not remain in the container when the sprinkler system is activated or during fire extinguishing.

- CB logo embossed in the removable front.

- Neutral gray livery with contrasting CB blue spring latch.

Would you like to know more about our options for automated warehouses?